Blue Elk Solar

When an abundance of rainfall made it difficult to construct temporary access roads for a project site, contractors called upon the experts at Ferguson Waterworks.

Challenge

After installing temporary roads, our customer was dissatisfied. Earlier in the spring, rainfall was abundant and the roads became unreliable. They required assistance and needed a new design plan to construct temporary access roads.

Solution

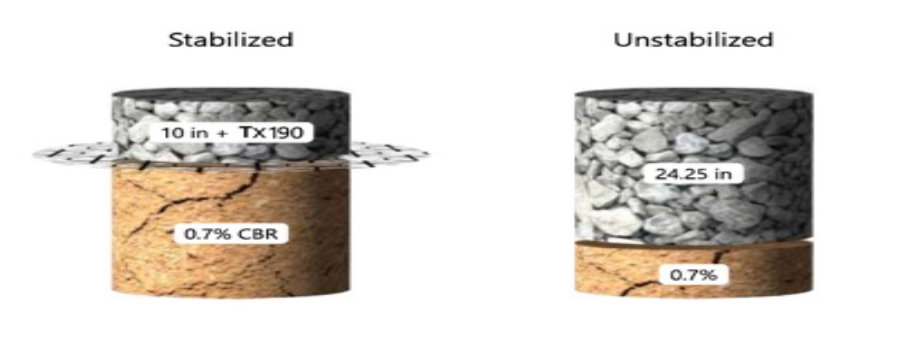

Ferguson provided on-site assistance, including running Dynamic Cone Penetration (DCP) testing to measure the strength of in-situ soil and the thickness and location of subsurface soil layers. As a result, we generated several design options for constructing the temporary access roads. Each design was specific to the location.

Since they were using a larger aggregate, the TX190L plan was selected. Compared to fabric, this option better suited the particular location which had soft spots.

Product Advantages

- Kept project on schedule

- Less stone required

- Able to use larger aggregate

- Reduce life cycle cost of haul road

Featured Product

- TX190

View Similiar Case Studies

In order to revitalize and meet stormwater codes, the abandoned parking area at the Shoppes at Fashion Square in Orlando, FL, required updates. With a permeable paving system and machine technology, we helped the client achieve their goals, save $1 million, and complete the project in just 10 days.

With solar panels in place and operational, an immediate and effective erosion control solution was imperative. Especially considering the panels were positioned next to channels, drip lines, and spillways.

After failed attempts to stabilize the earth at the Mt. Jackson Solar Farm, they required an immediate, cost-effective erosion control solution. Ferguson Waterworks was brought on board to address their ongoing concerns.