Retaining Wall Materials And Accessories

Providing comprehensive solutions and retaining wall materials for your earth stabilization project

When it comes to constructing retaining walls and slopes, high-quality materials are imperative for long-lasting stabilization and performance. Ferguson Waterworks provides civil engineers and construction professionals with a one-stop solution for geo and stormwater supplies. Call your local Ferguson Waterworks product specialist today for expert solutions, competitive pricing, and fast turnarounds. From uniaxial geogrids to geotextiles and drainage geocomposites, depend on our retaining wall materials and accessories to enhance the strength, stability, and longevity of your load-bearing structures.

Ferguson Waterworks distributes high-quality retaining wall materials and accessories in order to help facilitate your geo and stormwater projects from start to finish.

Ensure each component of your project is accounted for. Talk to your local representative to determine which stabilization fabrics, drainage materials, and accessories will optimize performance, longevity, and budget.

Sleeve-It® System: Prefabricated fence post anchoring solution

With its patent-pending design, the Sleeve-It system integrates stable fence footings directly into the segmental retaining walls (SRWs) during construction. As a result, the pre-engineered fence post anchor eliminates the need for post-installation foundations that often lack lateral stability. Not to mention, it is the only cantilevered code-complaint system for fences and rails placed within 36” of the SRW under IBC 1015.2. The SRW face consists of dry-stacked mortarless concrete units.

The Sleeve-It system ships fully assembled for quick, hassle-free installation and stacks easily for storage and transport. Furthermore, it provides resistance against overturning and sliding. Sleeve-It ensures secure fence post installation behind retaining walls, even when subjected to horizontal forces.

Tested under real-world conditions, the Sleeve-It prefabricated post-anchoring solution offers reliable performance in both residential and commercial applications.

- Reduce liability and risks

- Superior strength in comparison to cardboard tubing

- Maximize the value of usable real estate on top of the segmental retaining wall

- Reduce landscape maintenance costs

- Reduce labor expenses

- Eliminate auguring

Modular Block Retaining Wall

Easy and fast to install, modular block retaining walls offer construction professionals and civil engineers an innovative geosynthetic solution for retaining wall structures. A segmental block retaining wall system encapsulates engineered grout between geotextile layers – when saturated, the mat cures and creates a fiber-reinforced concrete sheet. Because of the reinforced fibers, the mat is flexible by nature. Therefore it moves with slight subgrade shifts, rather than cracking like traditional pavement solutions for slopes. Simply cut and manipulate the modular blocks system on-site to accommodate obstructions and abnormal geometries.

When should modular block retaining walls be installed?

Uses for modular block retaining walls extend across many sectors including mining, road, rail, civil, petrochemical, and agriculture projects. For comprehensive solutions, rely on Ferguson Waterworks for high-quality retaining wall materials.

Gravity Wall

These retaining wall systems stand upright due to the force of their own weight. In addition, gravity walls utilize a rigid structure and laterally support soils and aggregates. When on-site material is readily available and the most cost-effective option, gravity walls become an ideal candidate for grade separation. Support gravity retaining walls with geosynthetics to enhance long-term performance. For small-scale applications where geosynthetic reinforcement is unnecessary, gravity walls serve as an excellent option to optimize the project’s budget.

Natural Stone Retaining Wall Blocks

When a hard armor surface is required, select from our standard-size limestone blocks array. Civil engineers and construction professionals incorporate limestone block walls for both retaining walls as well as aquatic applications. Furthermore, this natural stone product provides a visually appealing solution for retaining walls. Select from rough-sized quarry blocks or precision-cut and dressed stones.

Gabion Retaining Walls

For high-load and abrasion-prone applications, gabions provide strong reinforcement. Commonly implemented in rivers and lakes that freeze, gabion retaining walls and revetments address grade changes by stacking and reinforcing a series of permeable gabion baskets. Geogrids and geotextiles benefit the system for additional reinforcement and filtration. Furthermore, to obtain higher abrasion resistance and to improve the front face strength, the front or one side of gabions can be produced with steel wire mesh 3.4 mm in diameter. The other faces of the gabion are a 2.7 mm diameter mesh. In order to reinforce the structure, all mesh panel edges are selvaged with a higher-diameter wire. Typically, sizes are 8” to 12” thick, 4’ wide, and 16’ to 40’ long.

Concrete Panel Walls

Commonly used for DOT work, concrete panel walls are large precast panels, oriented vertically. Typically, they are stabilized by soil nails, metal straps, steel, or geosynthetic reinforcement. Concrete panel walls are solid concrete, meaning they do not have integral insulation. Furthermore, because they sit completely vertically, they optimize the retaining wall’s footprint. Precast concrete wall panels are installed year-round and have long-term cost savings, exceptional durability, minimal maintenance, and more.

What are the IBC guardrail load requirements?

IBC SECTION 1015.2 – Guards shall be located along open-sided walking surfaces more than 30 inches measured vertically to the floor or grade below any point within 36 inches horizontally to the edge of the open side. For example, mezzanines, equipment platforms, aisles, stairs, ramps, and landings often require guards. Guards shall be adequate in strength and attached according to Section 1607.8.

IBC SECTION 1607.8.1 – Handrails and guards should resist a linear load of 50 pounds per linear foot according to Section 4.5.1.1 of ASCE 7. Glass handrail assemblies and guards shall comply with Section 2407.

Connect With An Expert Today

Case Studies

From solving challenging application issues to severe weather response, there is no better partner than Ferguson Waterworks. Let our past performance speak for itself.

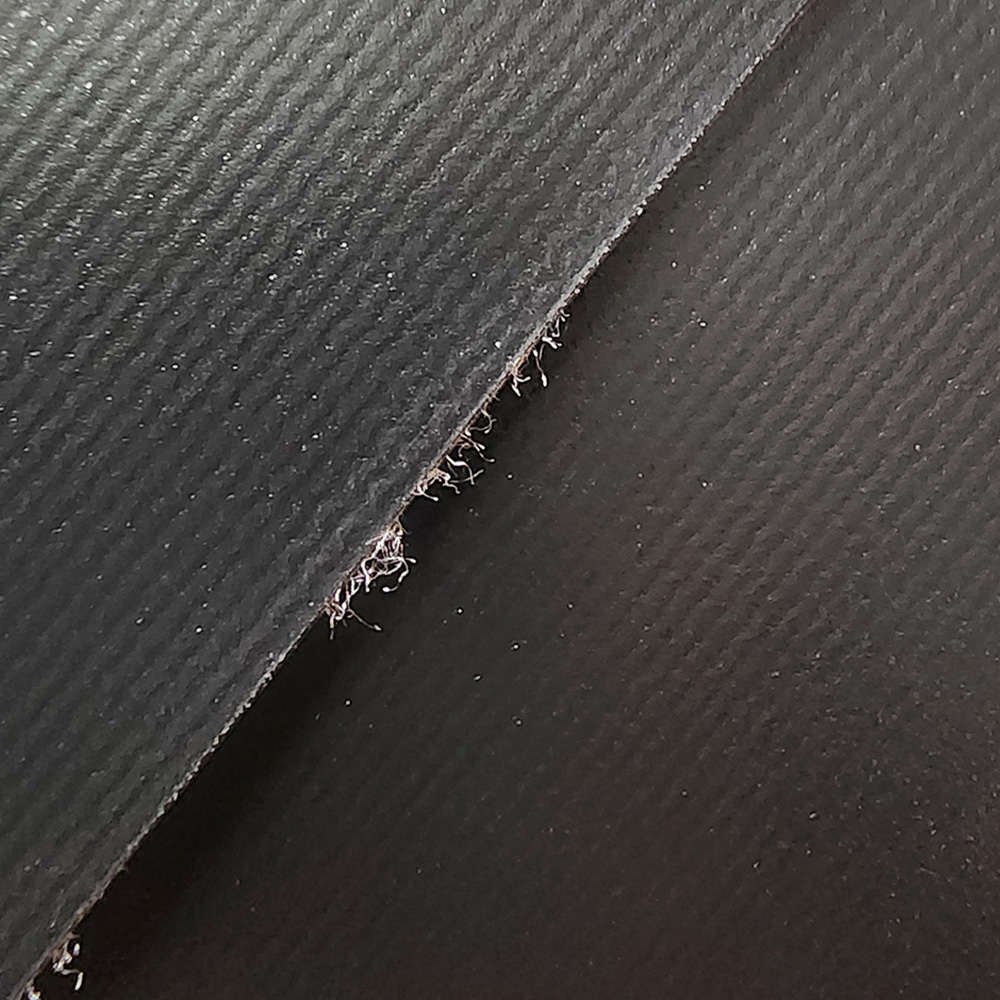

XR-5 Geomembrane Liners

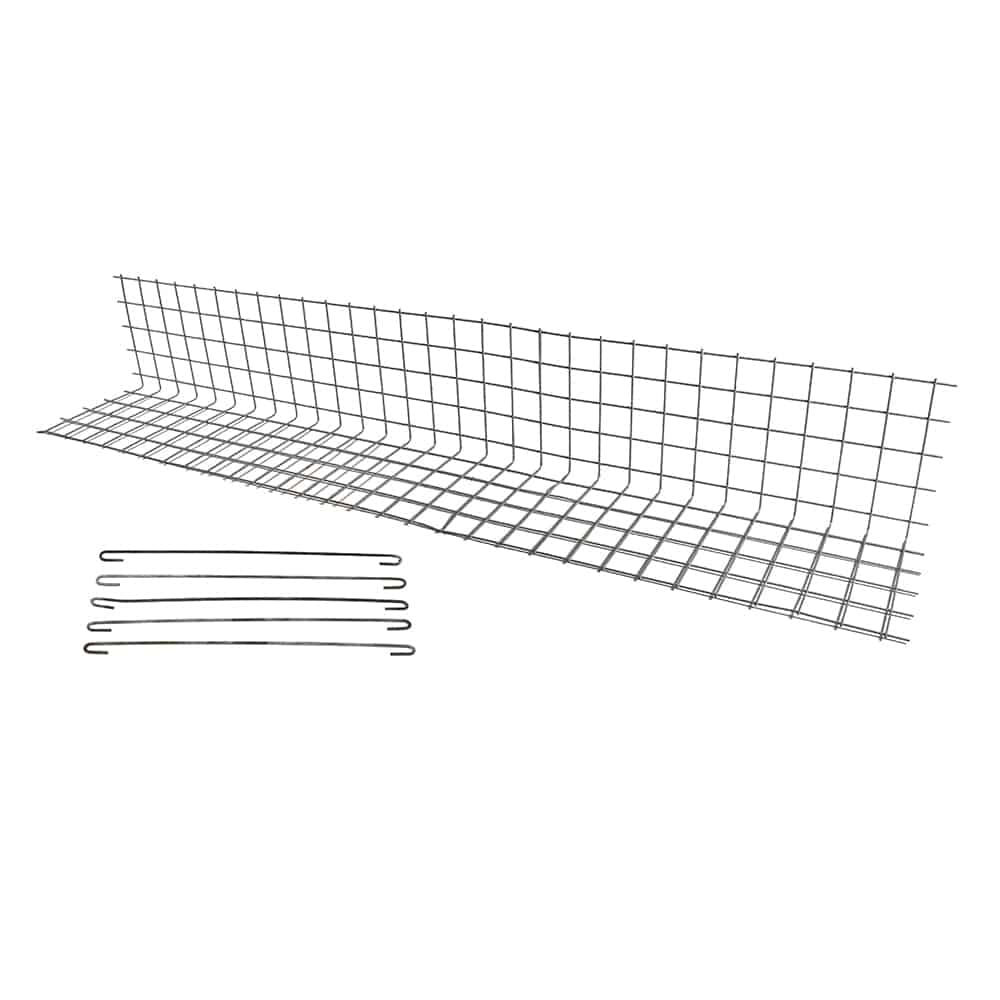

XR-5 Geomembrane Liners Wire Forms

Wire Forms Vegetated Walls

Vegetated Walls Vegetated MSE Walls

Vegetated MSE Walls Uniaxial Geogrids

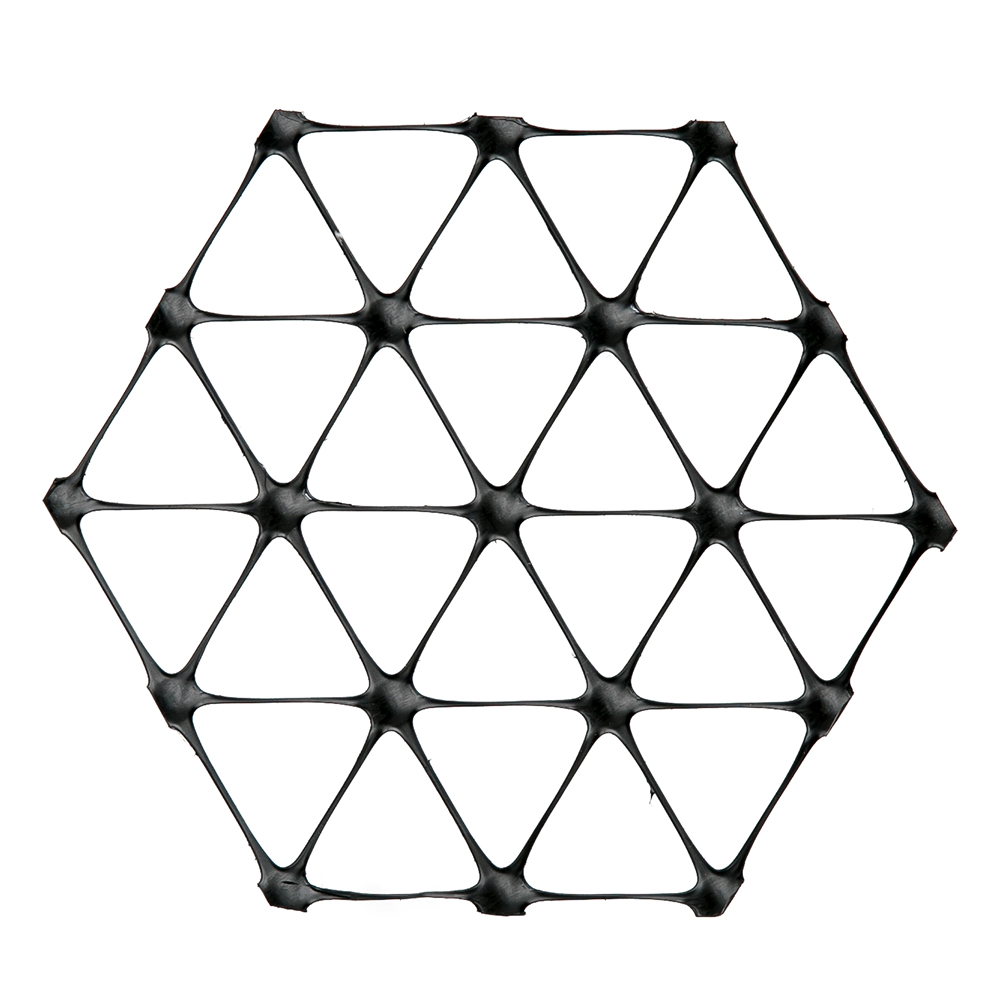

Uniaxial Geogrids Triaxial Geogrids

Triaxial Geogrids